OUR PRODUCTS

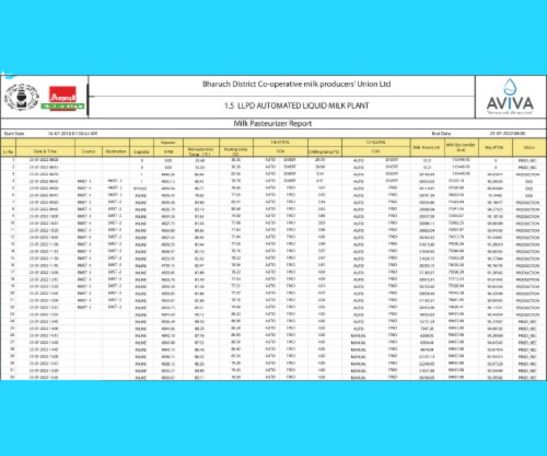

MILK PASTEURISATION PLANT

Our Designed pasteurizers are used to produce a wide range of dairy products such as liquid milk (whole / stan drained / skim), Paneer/cheese milk, yogurt milk, kefir milk, fresh cheese milk, whipping cream, Cream, and others, available in capacities from 500 – 30,000 LPH and provision manual Fully automated.

ICE CREAM PLANT

We, Diamond Engineering Works manufactures a wide range of high-quality Ice Cream Plants as per the specifications of our valued customers. The Composition of our plants includes among others, as Ageing Vats, Ice Cream Freezer, Homogenizers, Pasteurizing Vat, Churners, etc. Our Company is in this business, long-standing experience and rich knowledge of this business enable us to offer high-quality Ice Cream Plants to our valued customers at the most competitive prices. For the purpose, we have a modern manufacturing unit, well equipped with modern technology along with a team of highly qualified and experienced professionals, well versed with the complexities of this business.

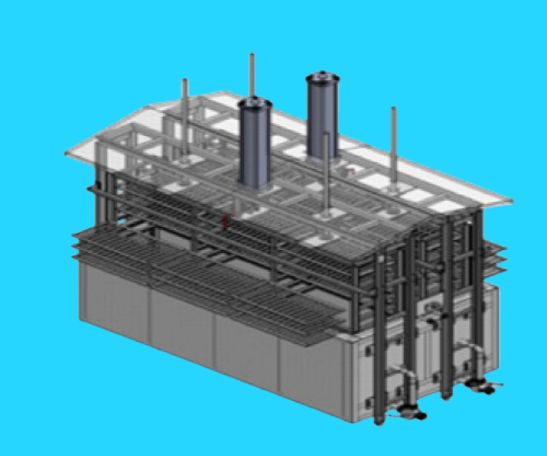

CIP PLANT

Cleaning of Equipment’s is the most critical job in food processing industry. Very effective cleaning of the equipment is required for hygienic processing and maintaining the quality of the product. The Automatic Cleaning-In-Place (CIP) system designed by us makes it possible to have very effective and economical cleaning of all types of process equipment and interconnecting pipes and fittings with minimum wastage of detergents and water. Applications: Dairy / Beverages / Food / Pharma.

EVAPORATIVE CONDENSERS

Step into the world of dairy excellence with Aviva!

We are committed to providing the best possible equipment and supplies for dairy processors in India.

AMMONIA PLANT

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

GHEE PLANT

We manufacture a comprehensive range of Ghee Boiling Kettles. These ghee boiling kettles are manufactured using premium grade raw materials and as per the prevai

ling quality standards of the industry. We also customized these kettles as per the specifications provided by our esteemed clients. Moreover, these are offered at competi tive market prices

MILK SILO & STORAGE TANKS

Various types of tanks in SS material are manufactured

with the required finish and quality. We use specially manufactured laser welded jackets for tanks.

– insulated tanks

– jacketed tanks

– outdoor silos

we have manufactured tanks from 100 liters to 150,000 liters capacity tanks tray

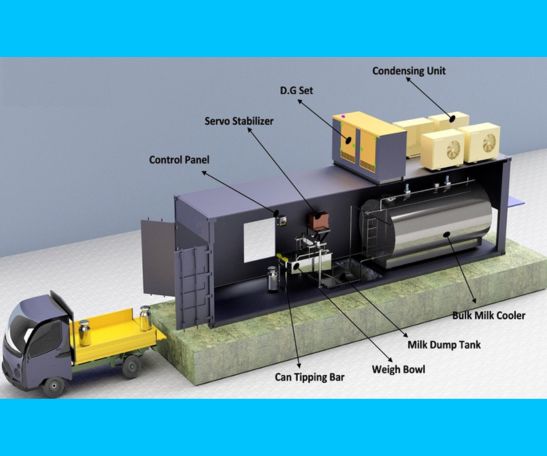

BULK MILK COOLER

A bulk milk cooler is a refrigeration unit used to store large quantities of milk. The milk is cooled to a temperature below 40 degrees Fahrenheit, which helps preserve the quality of the milk and extend its shelf life. Our dump tanks make it easy to dispose of wastewater quickly and easily, without any mess. And our milk pumps are reliable and efficient, making them perfect for busy dairy farms. Finally, our thermal plates help keep your food cold or hot, depending on your needs.

HALF CYLYNDRICAL BULK MILK COOLER

Tank capacity 500 ltr to 10000 ltr Tank orientation landscape.

40 lacs ltr of Milk Chilled, 701 units sold till now, more than 3600 farmers served. A refrigeration system manages this by removing heat from the milk and “rejecting” it with a specific refrigerant fluid.

CONTAINERIZED MILK CHILLING PLANT

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

BMC TANKS

The fully enclosed, Cylindrical horizontal range varies from 10000 Lts. It is compact, robust, and easy to clean. It can be installed indoors as well as outdoor.

AVIVA ROAD MILK TANKERS

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Industrial Washing Equipments

We deal in a diverse range of Equipments finishing equipment. Our company supplies Industrial Washing Equipment which

are available in various sizes in the market.

These automatic and auto-timed machines are capable of washing all kinds of spares. We follow the industrial standards and norms while manufacturing these high-tech machines.

Milk Weigh Bowl- Dump Tank

Our organization is counted among the most distinguished exporters and suppliers of Weigh Bowls. The offered bowls are widely used to weigh milk and also used for other

dairy products. These bowls are developed at the vendors’ premises using best grade steel, which is coated wit anticorrosives.Customers can avail these weigh bowls from us at market-leading prices

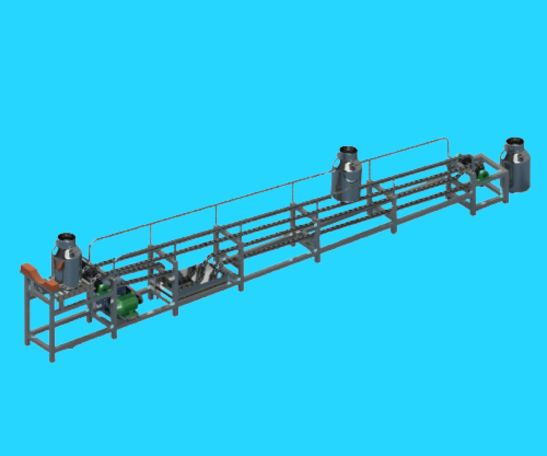

Milk Can & Crate Conveyor

We bring Milk Crate Conveyors, applicable in various FMCG and other types of industries. These are automatic systems with crate conveyors, which are highly useful in conveying of crates and boxes in a plant. Made from high quality raw materials, these Auto Crate Conveying Systems are highly

beneficial for all types of crates

Powder Mixing System

The shear pump is heart of powder mixing unit. Specially

designed shear pump along with Ventures suction of powder and dumping funnel are main components in skid.

– Pectin dissolving |

– Ice cream mix

– Starch and xanthan gum

Pressing Module With Panner hoops

These are designed and assembled under industry requirements using certified grade raw materials. Our paneer and cheese presses are reasonably priced and highly

acknowledged for their unique designs, durable construction, effective performance, corrosion resistance, and trouble-free operation

PANEER DIPPING VAT

Chilled Water Tank -Insulated Tank (Soaking tank) With Trolley and Cages With Pneumatic Lifting arrangement

Paneer Coagulation tank

Paneer Coagulation tank With Acid Spray Nozzles at the Top and Pneumatically actuated Citric acid dosing on/ Off

Valve With agitator with Lifting arrangments

Butter Melting Vat

Butter Melting Vat is used to melt the butter before making GHEE. Made of SS 304 with sanitary finish. Capacity can be designed as per requirements. Demanded in dairy and butter processing industries, TechQu provides this product with temperature control feature for melted butter and hot water

Butter Trolley

Aviva Equipments has gained immense recognition in offering a quality assured array of Butter Trolley. This trolley is widely

used for storing and keeping butter in large amount. Provided trolley manufactured with utmost precision by making use of

excellent grade metal alloy with the help of modern technology under the guidance of skilled professionals

Valve Cluster & Automation

Valve Cluster, which is an indispensable element of the highest level of automation and hygiene facilities, is one of the automation elements that Aviva Engineering specially designed for customer

needs with its high engineering quality. As Aviva Engineering, we design Valve Cluster according to customer needs and we make

automation integration by assembling the field after production. In

Valve Clusters

• Mixproof GEA/alfa laval/IDMC valves are used with ASI protocol

connection system.

• Normally Closed to Normally Open They are EHEDG Hygienic

Design certificate Valves with Material Analysis (3.1) and Material

Approval (2.2) certificates, which can be turned easily without any

additional parts.

• In addition, the need to keep spare parts in the facility is reduced

with only 3 different actuator options such as DN15-DN65,

DN80-100, DN125-150

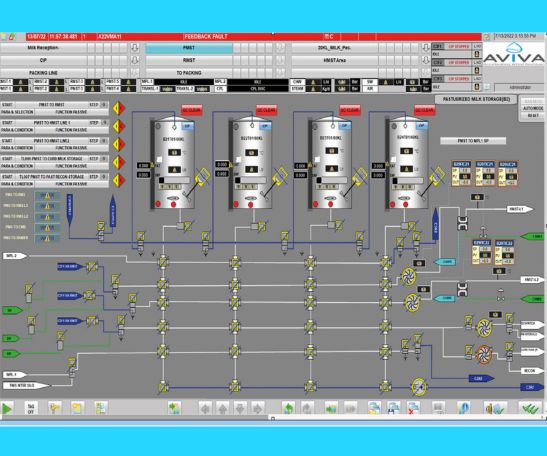

Automation Engineering

we provide automation solutions to the food & dairy processing industry. We also undertake revamping & moderniza

tion of the existing food processing plants to a suitable automation level.

Features

– process Automation Development as per Function

description & customer-specific process

– standardized MIS reports & SCADA development

– Complete Hardware supply solutions

– Competent team for development & commissioning

Automation software features

– Queuing function

– Product recovery by water push

– Interlocks

– Errors

– Password levels

– Equipment status memory (flag)

– Event log

– Alarm handling

– MIS Report

Tomato Processing

Complete lines for Tomato paste, sauce, juice, peeled/diced Tomatoes. We have developed innovative equipment to

process tomatoes into a variety of products, such as peeled tomatoes, diced tomatoes, pastes, ketchups, sauces, juices,

purees, and more. Tomatoes are blanched and pulped with water delivered from a high-end water filtration system, following which their juice / concentrate is extracted using

hot break and cold break technology using single and doublestage Turbo Extractors. They are then sterilized and pasteurized and go through an aseptic filler designed especially for viscous food products. Finally, they are packaged to retain their freshness, resulting in a high-quality end product.

Fruit Puree

Complete processing lines for all kinds of Fruits & Clear Juices. The increased interest in improved health has led to a higher demand for fruits and vegetables juices. Our clear juice processing line is designed to produce and process clear juice from apples, berries, cherries, and pomegranates. Fruit sterilization, first- and second-stage extraction, concentration, clarification, pulp purification, and aseptic processing are the stages in which clear fruit juices are

produced in an extremely gentle manner and a temperature-controlled environment to retain their original flavor and colour. Advanced heat treatment and falling film evaporation technology is then used to fill and package the juices, keeping them fresh for months

Fruit & Clear Juices

Complete processing lines for all kinds of Fruits & Clear

Juices. The increased interest in improved health has led to

a higher demand for fruits and vegetables juices. Our clear

juice processing line is designed to produce and process

clear juice from apples, berries, cherries, and pomegrana

tes. Fruit sterilization, first- and second-stage extraction,

concentration, clarification, pulp purification, and aseptic

processing are the stages in which clear fruit juices are

produced in an extremely gentle manner and a temperatu

re-controlled environment to retain their original flavor

and colour. Advanced heat treatment and falling film evapo

ration technology is then used to fill and package the juices,

keeping them fresh for months.

Aseptic Plants

The latest technology for Sterilization & Aseptic filling. Aseptic

processing involves the packaging of primarily liquid products

under highly sterile conditions of products that can be stored at

room temperature without requiring refrigeration. This prolongs

their life from months to years. The main steps include thermal

sterilization, packaging material sterilization, and maintenance

of sterility in the packaging process. Our aseptic plants are

equipped with state-of-the-art technology to ensure Ultra-High

Temperature (UHT) Sterilization, including Mono Head Aseptic

Fillers, Double Mobile Head Aseptic Fillers, and mixing tanks for

diced products, Tube-in-tube Sterilizers, and Piston Pumps for

diced products. Our plants function under strict regulations to

ensure a completely sterile environment for the processing and

packaging of foods

DX-CCH 5000 Ltr

The fully enclosed, Cylindrical horizontal range varies from 3000-5000 Lts. It is compact, robust, and easy to clean. It can be installed indoors as well as outdoor.

DX-CCCH 10,000 Ltr

The fully enclosed, Cylindrical horizontal range varies from 10000 Lts. It is compact, robust, and easy to clean. It can be installed indoors as

well as outdoor

DX-HCH

the half-cylindrical horizontal, range varies from 1000-2000 Lts. It is easy to use, and clean and can be equipped with a manual & automatic washing system

Type : Model – Neno Mobile

Mobil Trolley (M.S) Signal cow Can 20/Lt, Single

Milking Time 10-12/Cow or Buffalo par hour

Size : H 900 x L 900 x W 400

Weight : 50 Kg.

Vacuum Pump capacity : 250 Lt / min

Motor Power : 0.5 hp.

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket : 20 Lt, 304 S.S (ISO 9001)

Vacuum tank capacity : 5 Lt.

Chassis : 32×2 mm pipe with oil paint coated

Wheel size : 200×50 mm

Milk hose : Silicone food grade, L3000 mm, od 24 mm, Id14 mm

Vacuum hose : L 3000 mm, D 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 10 – 12 cow / hour

Type : Model – SL1 Mobile

Mobil Trolley (M.S) Signal cow Can 25/Lt, Single

Milking Time 12-15/Cow or Buffalo par hour

Size : H 900 x L 900 x W 400

Weight : 60 Kg.

Vacuum Pump capacity : 350 Lt / min

Motor Power : 1 hp.

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket : 25 Lt, 304 S.S (ISO 9001)

Vacuum tank capacity : 5 Lt.

Chassis : 32×2 mm pipe with oil paint coated

Wheel size : 200×50 mm

Milk hose : Silicone food grade, L3000 mm, od 24 mm, Id14 mm

Vacuum hose : L 3000 mm, D 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 12 – 15 cow / hour

Type : Model – S1 Mobile

Mobil Trolley (M.S) Signal cow Can 40/Lt, Single

Milking Time 12-18/Cow or Buffalo par hour

Size : H 1100 x L 900 x W 700

Weight : 75 Kg.

Vacuum Pump capacity : 350 Lt / min

Motor Power : 1.5 hp.

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket :30 Lt, 304 S.S (ISO 9001)

Vacuum tank capacity : 25 Lt.

Chassis : 32×2 mm pipe with oil paint coated and s.s

Wheel size : 255×50 mm

Milk hose : Silicone food grade, L3600 mm, od 24 mm, Id14 mm

Vacuum hose : L 3400 mm, od 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 10 – 15 cow / hour

Type : Model – SE2 Mobile

3Mobil Trolley (M.S) Double cow Can 40/Lt, Single

Milking Time 25-30/Cow or Buffalo par hour

Size : H 1100 x L 900 x W 700

Weight : 100 Kg.

Vacuum Pump capacity : 400 Lt / min

Motor Power : 1.5 hp.

Engine : Hond petrol

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket : 40 Lt, 304 S.S (ISO 9001)

Vacuum tank capacity : 25 Lt.

Chassis : 32×2 mm pipe with oil paint coated

Wheel size : 255×50 mm

Milk hose : Silicone food grade, L3600mm, od 24 mm, Id 14 mm

Vacuum hose : L 3400 mm, D 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 22 – 25 cow /

Type : Model – S2 Mobile

Mobil Trolley (M.S) Double cow Can 40/Lt, Single

Milking Time 20-25/Cow or Buffalo par hour

Size : H 1100 x L 900 x W 700

Weight : 100 Kg.

Vacuum Pump capacity : 400 Lt / min

Motor Power : 1.5 Hp.

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket : 40 Lt, 304 S.S (ISO 9001)

Vacuum tank capacity : 25 Lt.

Chassis : 32×2 mm pipe with oil paint coated

Wheel size : 255×50 mm

Milk hose : Silicone food grade, L3600mm, od 24 mm, Id 14 mm

Vacuum hose : L 3400 mm, od 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 22 – 25 cow

Type : Model – S3 Mobile

Mobil Trolley (M.S) Double cow Can 20/Lt, Double

Milking Time 25-30/Cow or Buffalo Par hour

Size : H 1100 x L 900 x W 700

Weight : 115 Kg.

Vacuum Pump capacity : 400 Lt / min

Motor Power : 1.5 hp.

Working voltage : 230 v, 50 Hz, 1440 Rpm

Bucket : 22 Lt, Double 304 S.S (ISO 9001)

Vacuum tank capacity : 25 Lt.

Chassis : 32×2 mm pipe with oil paint coated

Wheel size : 255×50 mm

Milk hose : Silicone food grade, L3600mm, od 24 mm, Id 14 mm

Vacuum hose : L 3400 mm, D 14 mm, Id 8 mm

Pulsator : 60-40 type

Milking capacity : 22 – 25 cow / hour