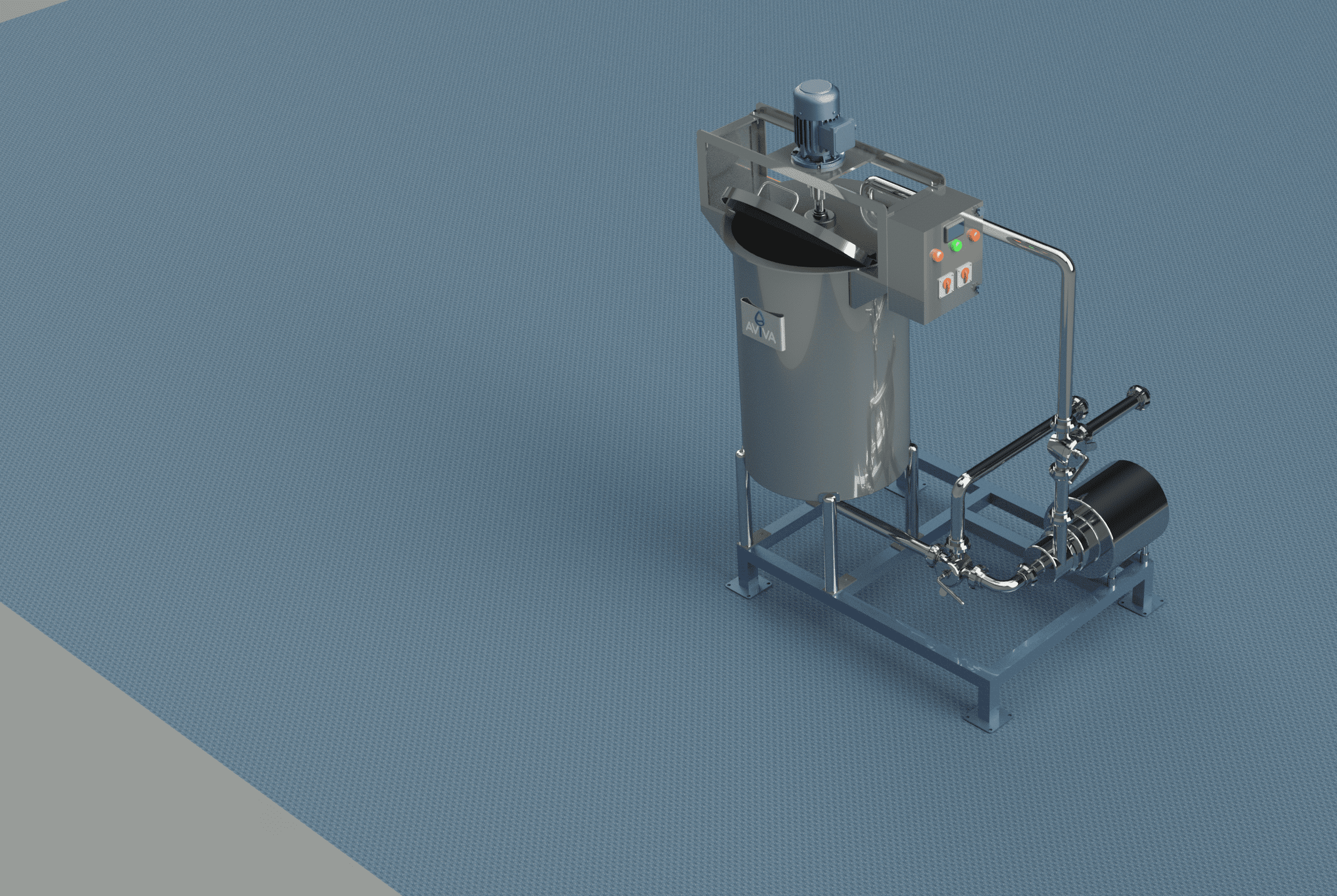

Milk Filter Tanks Manufacturer

Milk filters and tanks play essential roles in dairy processing, ensuring that milk is clean, safe, and of high quality before reaching consumers. Here’s a detailed description of each component:

Milk Filters

Milk filters are used to remove impurities and debris from raw milk. These impurities can include dirt, straw, hair, and other particulate matter that may have been introduced during milking. Proper filtration is crucial to maintain milk quality and safety.

Types of Milk Filters

- Inline Filters: These are installed directly in the milk transfer lines and filter milk as it flows through the system.

- Sock Filters: These are cylindrical filters that milk flows through, trapping debris inside the filter material.

- Plate Filters: Consist of a series of flat filter plates arranged in a frame, through which milk is passed and filtered.

Features

- Filtration Material: Usually made of fine mesh, cotton, or synthetic fibers.

- Flow Rate: Designed to handle the volume of milk being processed without significant resistance or pressure drop.

- Ease of Cleaning: Should be easy to clean or replace to ensure hygiene and prevent bacterial growth.

Milk Tanks

Milk tanks are used for storing, cooling, and sometimes transporting milk. They come in various sizes and configurations depending on the needs of the dairy operation.

Types of Milk Filters

- Bulk Storage Tanks: Large tanks used on farms or at processing facilities to store milk before it is transported or processed.

- Cooling Tanks: Tanks equipped with refrigeration units to quickly cool milk to preserve its quality and prevent spoilage.

- Transport Tanks: Insulated tanks mounted on trucks for transporting milk from farms to processing plants.

Features

- Material: Typically made of stainless steel to prevent contamination and ensure durability.

- Insulation: Well-insulated to maintain the desired temperature.

- Agitation System: Keeps milk uniformly mixed to prevent cream from separating.

- Cleaning Systems: Often equipped with CIP (Clean-In-Place) systems for thorough and efficient cleaning.

Integration in Dairy Processing

- Receiving: Raw milk is received and initially filtered to remove any large debris.

- Cooling: Milk is rapidly cooled in cooling tanks to a temperature that inhibits bacterial growth.

- Storage: Cooled milk is stored in bulk tanks until it is ready for further processing or transport.

- Transport: Milk is loaded into transport tanks and delivered to processing facilities.

Importance

- Quality Control: Filters ensure that only clean milk proceeds to storage and processing, which is crucial for high-quality dairy products.

- Safety: Properly filtered and stored milk reduces the risk of contamination and spoilage.

- Efficiency: Efficient filtering and cooling systems help maintain continuous and smooth dairy operations, reducing downtime and waste.

This high-capacity pasteurizer is an integral component of any large-scale dairy operation, ensuring milk is safely processed and ready for consumption or further processing.