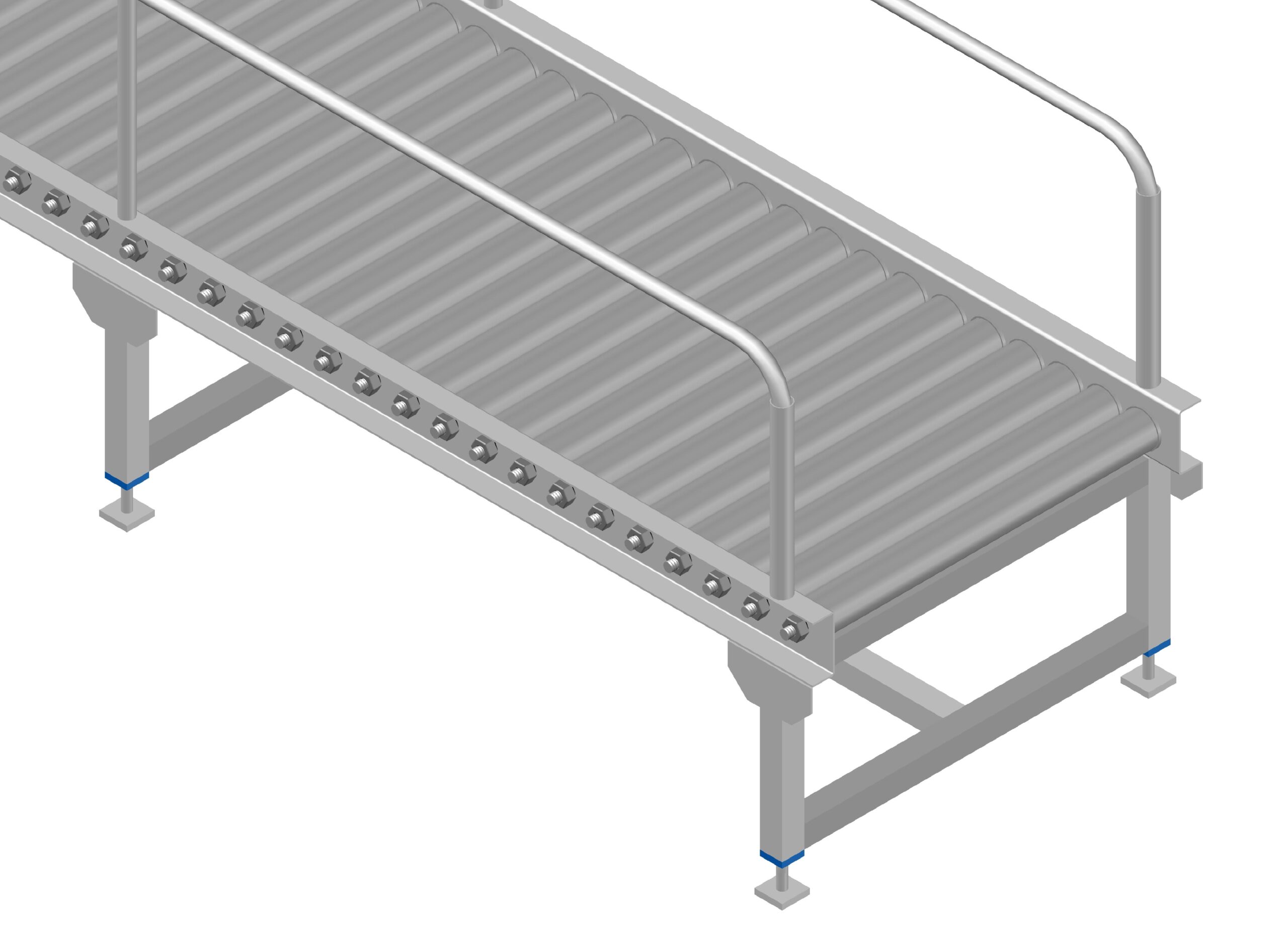

Gravity Roller Conveyor for Milk Cans

A Gravity Roller Conveyor for Milk Cans is a conveyor system designed to facilitate the movement of milk cans using gravity. In summary, a Gravity Roller Conveyor for Milk Cans is a specialized conveyor system designed for the smooth and efficient transportation of milk cans using gravity, commonly employed in the dairy industry.

AEPL Offer a Standard 5-meter-long conveyor with a width of 450 mm can transfer 40-50-liter milk cans from a Receiving dock to a tipping bar. Typically, This Types of Made from SS 304 or Mild Steel Material & conveyor consists of rollers with a diameter of 2 inches (51mm) or 63mm.

The Design of Roller is strong enough to withstand the Impact of Milk CAN filled 40 liters with milk and dropped from the height of approx. 150 mm

Features

- Available in SS 304, & Mild Steel Material

- Structure C – Channel Type

- Roller – Nylon Bushing, Bearing or Gun Metal Bushing

- Adjustable Legs for Maintain Slops

- Roller Distance – 85 mm

- Side Support Relying

Technical Specifications

- Conveyor Type: Straight & Available in Curve Shape Also.

- Capacity: Conveyor can Carry Filled Milk Cans up to 50 kg/feet

- Usage/Application: Transport Milk Can by Gravity

- Weight: Depends on the Conveyor Length.

- Customization: The company offers customization options for their Conveyor to meet the Different Plants Layout

- Side Support Relying: A 250 mm Height Side Relying for Can Support.

- Tipping Bar: A Tic Wood or Nylon Tip Bar Attached with Conveyor to Easily Dump Milk Cans into Weigh

- Roller Stud: - A Solid Round Bar