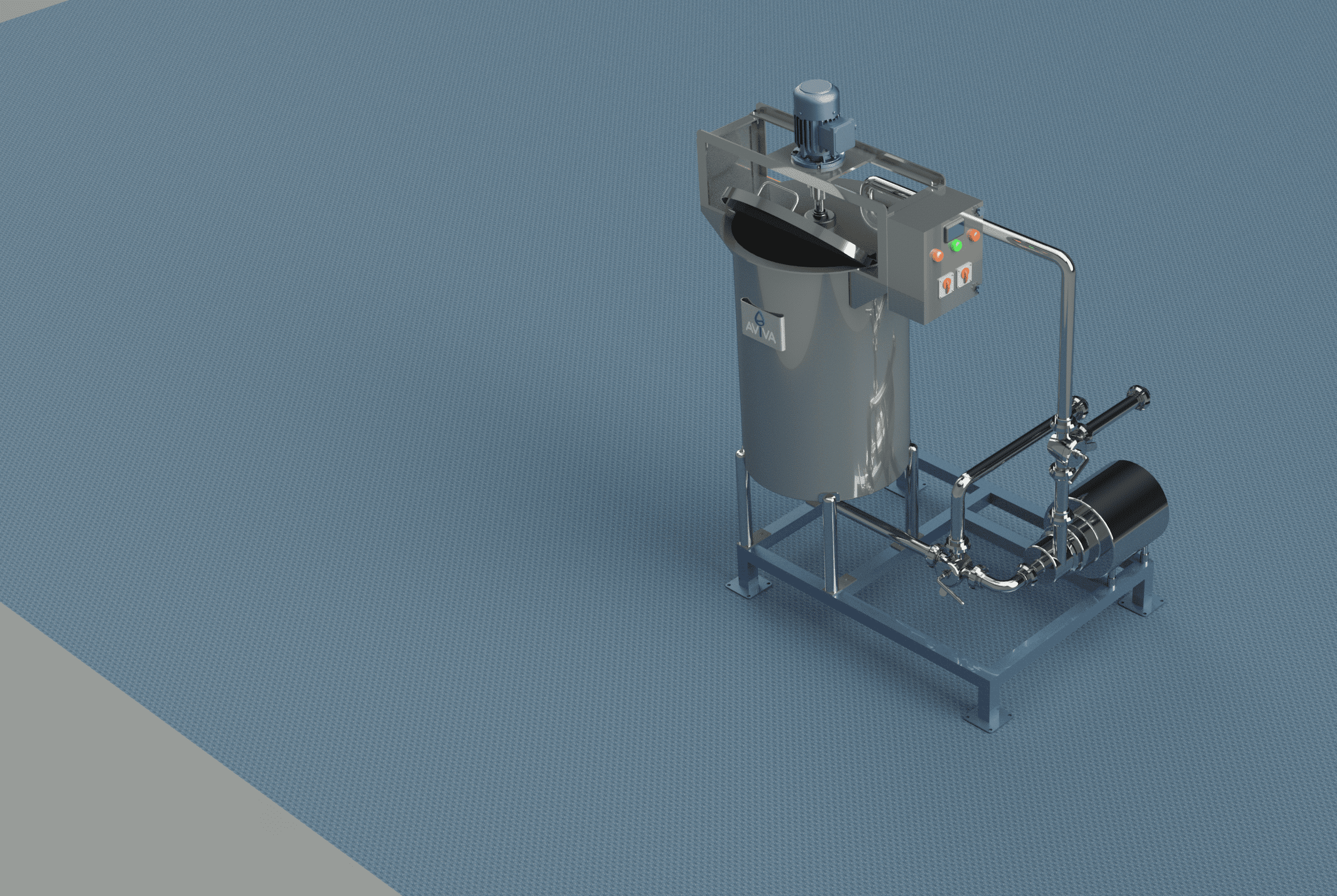

Bulk Milk Cooler 2000 Ltr

A Bulk Milk Cooler (BMC) is a large storage tank used by dairy Industries to Chilling Raw Milk. It’s a Main Part of dairy Industry & Dairy Products Process Plants, These Tanks usually made from stainless steel, and is cleaned by CIP after Complete each milk collection.

Aviva’s Bulk Milk Cooler 2000 Ltr available in Open & Close Type Design with an automatic cooling control unit and a Compact Control Panel with digital display to Easily Operate Complete BMCU System. The tank Having a 75 mm Thickness Polyurethane foam Insulation (Density 40 Kg)Injected by Machine. To Maintain Chilled Milk at Temp 4°CAEPL 2KL BMC Deigned by Special Construction, which allows them to Chilled milk 20 times faster. BMC have a 01 Nos Agitator with the RPM30- 32, to ensures the milk is the same temperature throughout the Day and prevents warm milk in the middle.

Features

Design: Unique, Occupies minimal space

- Temperature control: Digital temperature controller, advanced digital Technology to Control & Maintain temperature

- Cooling: Faster cooling due to direct expansion, energy efficient condensing unit

- Tank: Durable, AISI-304 S.S. Tanks with insulation

- Maintenance: User-friendly, low maintenance

- Electricity: Reduced electricity consumption

- Protection: Inbuilt anti-freezing protection system

- Microprocessor: Maintains temperature

- Agitator: Continuously rotates milk to maintain a uniform state

- Min Capacity of Milk Chilling Design –Special Design Omega Pillow Plates to Chill Milk Min 100 Liter Capacity Only by Operate one Condensing Unit at a Time

Technical Specifications

Design: Unique, Occupies minimal space

- Rated capacity: 2000 liters

- Gross capacity: 2000 liters

- Construction of Tank: AISI SS 304

- Tank Orientation– Open Type in D Shape

- Completely closed type in Shape of Elliptical & Horizontal

- Tank Evaporator– Omega Make Laser welded with Operating pressure of 30 bars and crash test pressure of 60 bars.

- Inner thickness: 2 mm AISI SS 304

- Outer thickness: 1.5 mm AISI 304

- Milk measuring facility: Inside Wall Mounted Dip stick &Calibration accuracy- 0.5%. Laminated & Framed calibration chart.

- Agitators– 01 Nos to Maintain Milk Temp & Compliance ensuring even distribution of the milk fat.

- Type of Insulation - 100 mm thkInjected, CFC Free PUF 40kg/Cu. m. with the 0.019 Wm/k

- CIP Facility – Rotary Spray Ball 01 Nos for Inside Complete Cleaning

- Voltage range - Input Volts: 300 to 550 for 3-phase BMC Out Put Volts: 415

- Manway – For Close Type BMC a Locking Type Manway Top Mounted

- Open Cover – For Open Type BMC 02 Nos Left Right Hydraulic Hinges Cover

- Ball Fit – Adjustable 50 mm Height Solid Ball Fit to Leveling the Tank

- Ladder – For Close Type BMC a Front Side Heavy Duty Ladder made from Pipes & Plates to approaching manway

- Air vent – an Air vent top Mounted to Prevent Vacuums Generation During Milk Pump Milk Out Process

- Temperature Sensor – Sub Zero

- Inlet – No Foam Inlet

- Pipe Line & Accessories - SS 304 Dairy Standard Union, NRV, 3 Way Valves etc. to Smooth Milk Loading Unloading Process in BMC.

- Servo Stabilizer: - 15 KVA – 2 Phase or 1 Phase

- D.G Set Require – 15 KVA (Optional on Demand)– 2 Phase or 1 Phase

Standard Applicable Cooling Time – First milking cycle (appx 50% to 60% of rated capacity of BMC tank) Cooling in less than 3 hours from 35C to 4°C- Second milking cycle (appx. 40% to 50% of rated capacity of BMC tank) cooling in 1hour 30 minutes (average temp 19.5 C to4°C)