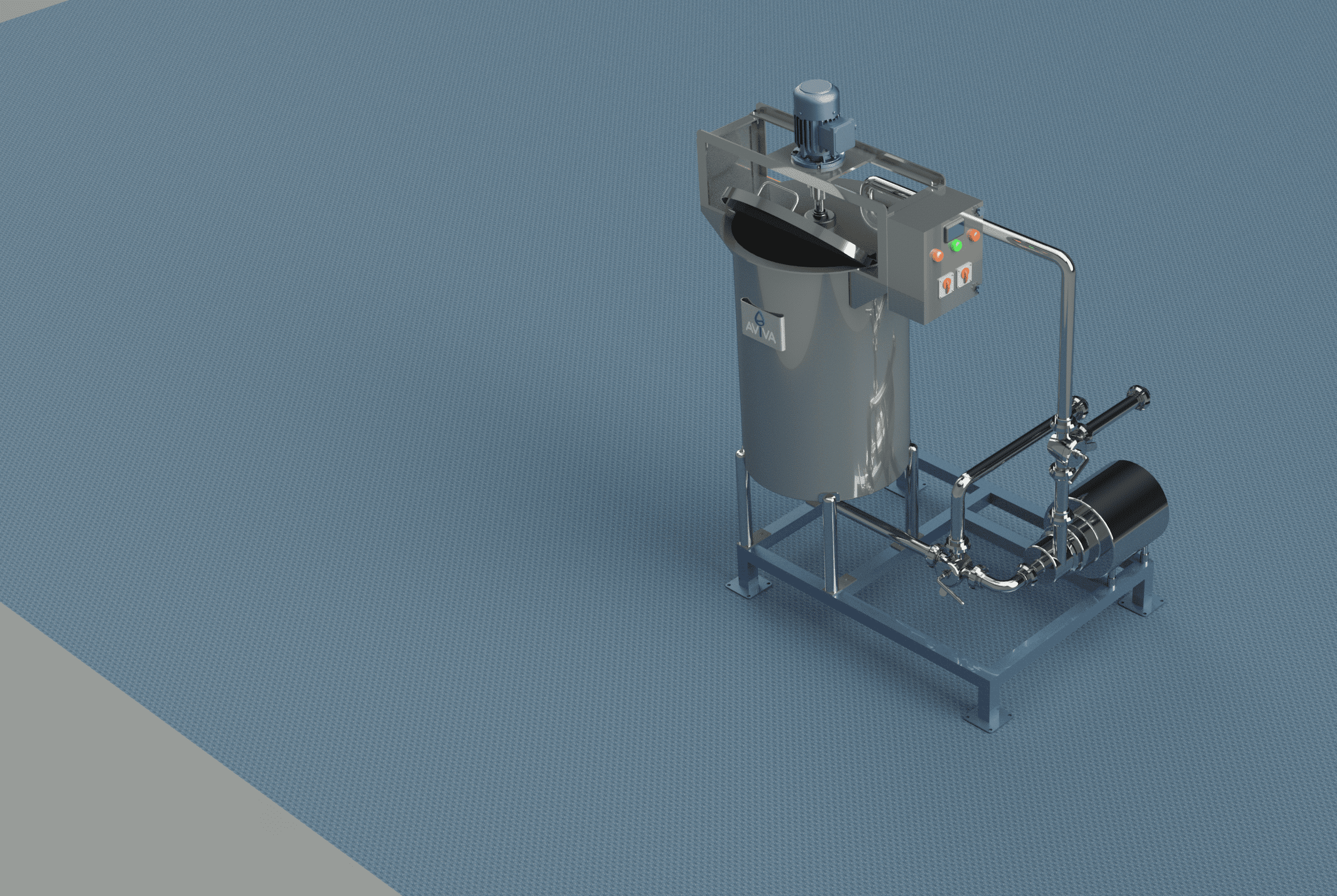

Batch Pasteurizer Tank & Systems

Batch Pasteurizer Tank with peripheral heating, usually built for small dairies. The pasteurizer is heating batches of milk to a 72°, and hold it for 30 minutes, before cool it down to the desire’s temperatures.

Higher pasteurization temperatures and longer holding time are available for different milk products.

AEPLoffers batch pasteurizer tanks for the food and beverage industries. These tanks are designed for heating and pasteurizing various liquids and ingredients, such as milk, juice, and beer. They are made of high-grade stainless steel for durability and easy cleaning, ensuring compliance with food safety regulations.

Features

- Capacity: The tanks come in a variety of sizes, ranging from small tanks with a capacity of 100 liters to large tanks with a capacity of 1,000 liters, to meet different production needs.

- Pasteurization systems: The tanks are equipped with pasteurization systems that use heat to kill bacteria and microorganisms, ensuring the safety and quality of the final product.

- Pasteurization systems: The tanks are equipped with pasteurization systems that use heat to kill bacteria and microorganisms, ensuring the safety and quality of the final product.

- Temperature control: The tanks are equipped with temperature control systems to maintain optimal pasteurization conditions.

- Automation: The tanks can be equipped with automation systems for monitoring and controlling various parameters such as temperature and pasteurization time.

- Customization: The company offers customization options for their batch pasteurizer tanks to meet the specific needs of different customers and applications.

AEPLbatch pasteurizer tanks are ideal for a wide range of applications in the food and beverage industries, providing efficient and consistent pasteurization results. The company also offers after-sales service and maintenance for their tanks to ensure their longevity and optimal performance.