Can Reception Section

The can reception section in a dairy industry is where raw milk is received, stored, and inspected in

hygienic conditions before processing.

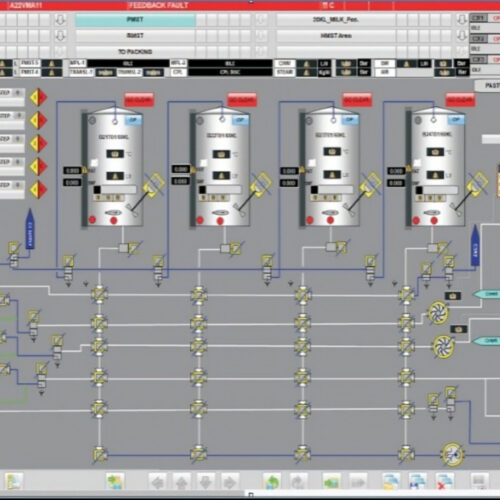

Scada Based Automation

SCADA-based automation refers to the use of Supervisory Control and Data Acquisition (SCADA)

systems to monitor and control industrial processes and operations in real-time.

Ice Cream Plant

The can reception section in a dairy industry is where raw milk is received, stored, and inspected in

hygienic conditions before processing.

Recon Section

The recondensing section recovers and condenses vapors from evaporation processes, often used

in dairy plants to improve energy efficiency and minimize product loss

Processed Milk Storage Section

The processed milk storage section holds pasteurized milk in insulated, temperature-controlled

tanks to maintain freshness and quality before packaging or further processing.

UHT Plant

A UHT (Ultra-High Temperature) plant sterilizes milk or liquid products by heating them to 135-150°C

for 2-5 seconds, ensuring a long shelf life without refrigeration while preserving nutritional value

PCC Panel Section

The PCC panel section manages and distributes electrical power to plant equipment, ensuring

efficient operation and safety

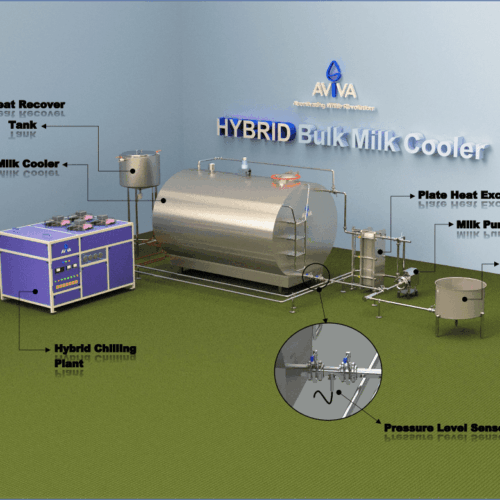

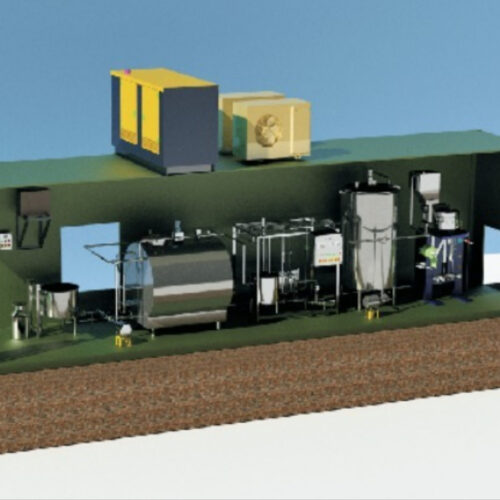

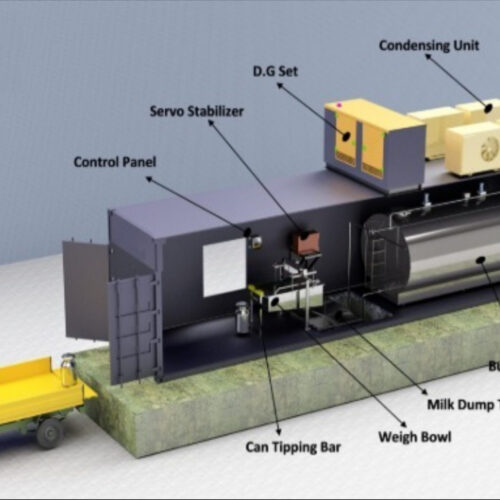

Mini Milk Processing Plant 20KLPD

A mini milk processing plant with a capacity of 20 KLPD (kiloliters per day) processes raw milk into

various dairy products like pasteurized milk, cream, and butter.

Process Plant

A UHT (Ultra-High Temperature) plant sterilizes milk or liquid products by heating them to 135-150°C

for 2-5 seconds, ensuring a long shelf life without refrigeration while preserving nutritional value

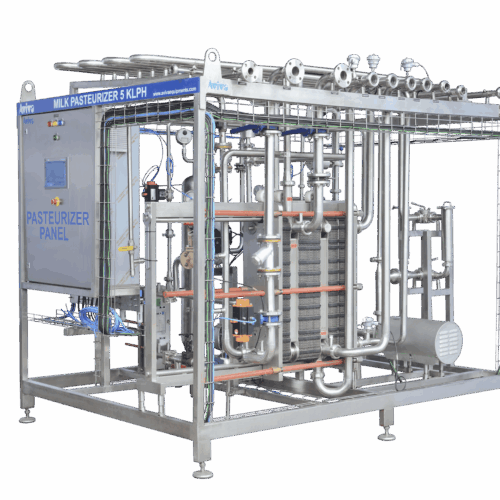

Cream Pasteurizer

A cream pasteurizer in the dairy industry heats cream to a specific temperature to kill harmful

bacteria, ensuring safety and extending shelf life while preserving quality