Road Milk Tankers Single & Multi Compartments

Road milk tankers are specialized vehicles designed for the transportation of liquid milk. They come in various configurations, including single and multi-compartment designs, each with specific features tailored to maintain the quality and safety of the milk during transport. Here’s a detailed description of each type:

Single-Compartment Milk Tankers

Description

- Structure: Single-compartment milk tankers have one large, insulated tank.

- Capacity: The capacity varies, typically ranging from 5,000 to 25,000 liters, depending on the size of the tanker.

- Material: Tanks are usually made of stainless steel to prevent contamination and ensure durability.

- Insulation: These tanks are insulated to maintain the milk at a constant, cool temperature, preventing spoilage during transportation.

- Insulation: These tanks are insulated to maintain the milk at a constant, cool temperature, preventing spoilage during transportation.

- Pumping System: Includes a pumping system for easy loading and unloading of milk.

- Temperature Control: May include temperature monitoring systems to ensure milk is kept within the required temperature range.

Advantages

- Simplicity: Easier to clean and maintain due to the single compartment.

- Cost-Effective:Generally less expensive to manufacture and operate compared to multi-compartment tankers.

- Suitable for Large Quantities: Ideal for transporting large volumes of milk from a single source to a single destination. Disadvantages:

Disadvantages:

- Less Flexibility: Not suitable for carrying different types of milk or milk from different sources simultaneously.

Multi-Compartment Milk Tankers

Description

- Structure: Multi-compartment milk tankers have two or more separate, insulated compartments within a single tanker.

- Capacity: The total capacity can be similar to single-compartment tankers but divided among multiple compartments, typically ranging from 5,000 to 25,000 liters in total.

- Material: Also made of stainless steel for hygiene and durability.

- Insulation: Each compartment is individually insulated to maintain the temperature of the milk.

- Cleaning Systems: Each compartment has its own CIP system for efficient and hygienic cleaning.

- Pumping System: Includes multiple pumping systems to handle loading and unloading from different compartments.

- Temperature Control: Each compartment may have its own temperature monitoring system to ensure proper temperature control for each batch of milk.

Advantages

- Flexibility: Can transport different types of milk or milk from different sources simultaneously without mixing.

- Efficient Use of Space: Allows for the transportation of smaller quantities of milk, which can be beneficial for smaller farms or dairies.

- Operational Efficiency: Can deliver milk to multiple destinations without the need for separate trips.

Disadvantages:

- Complexity: More complex to clean and maintain due to the multiple compartments.

- Higher Cost:Generally more expensive to manufacture and operate compared to single-compartment tankers.

Common Features

Regardless of the type, both single and multi-compartment milk tankers share some common features:

- Hygienic Design: Smooth internal surfaces to prevent milk residue buildup and bacterial growth.

- Safety Features: Equipped with safety measures like pressure relief valves and emergency shut-off systems.

- Compliance: Designed to meet regulatory standards for food safety and transportation.

Choosing between a single-compartment and a multi-compartment milk tanker depends on specific operational needs, including the volume of milk to be transported, the number of milk sources, and the destinations.

Related Products

Milking Machine

Milking Machine Manufacturer in India Home AVIVA Equipment Pvt. Ltd. is a leading milking machine manufacturer in India. With a strong commitment to innovation…

Ghee storage and settling tanks

Ghee storage and settling tanks Home Ghee storage and settling tanks Ghee storage & Settling tanks are used by dairy plants to safely store…

Side Agitators

Side Agitators Home Side Agitators Side agitators are mechanical devices used in various industrial processes to mix, agitate, or maintain the homogeneity of liquids…

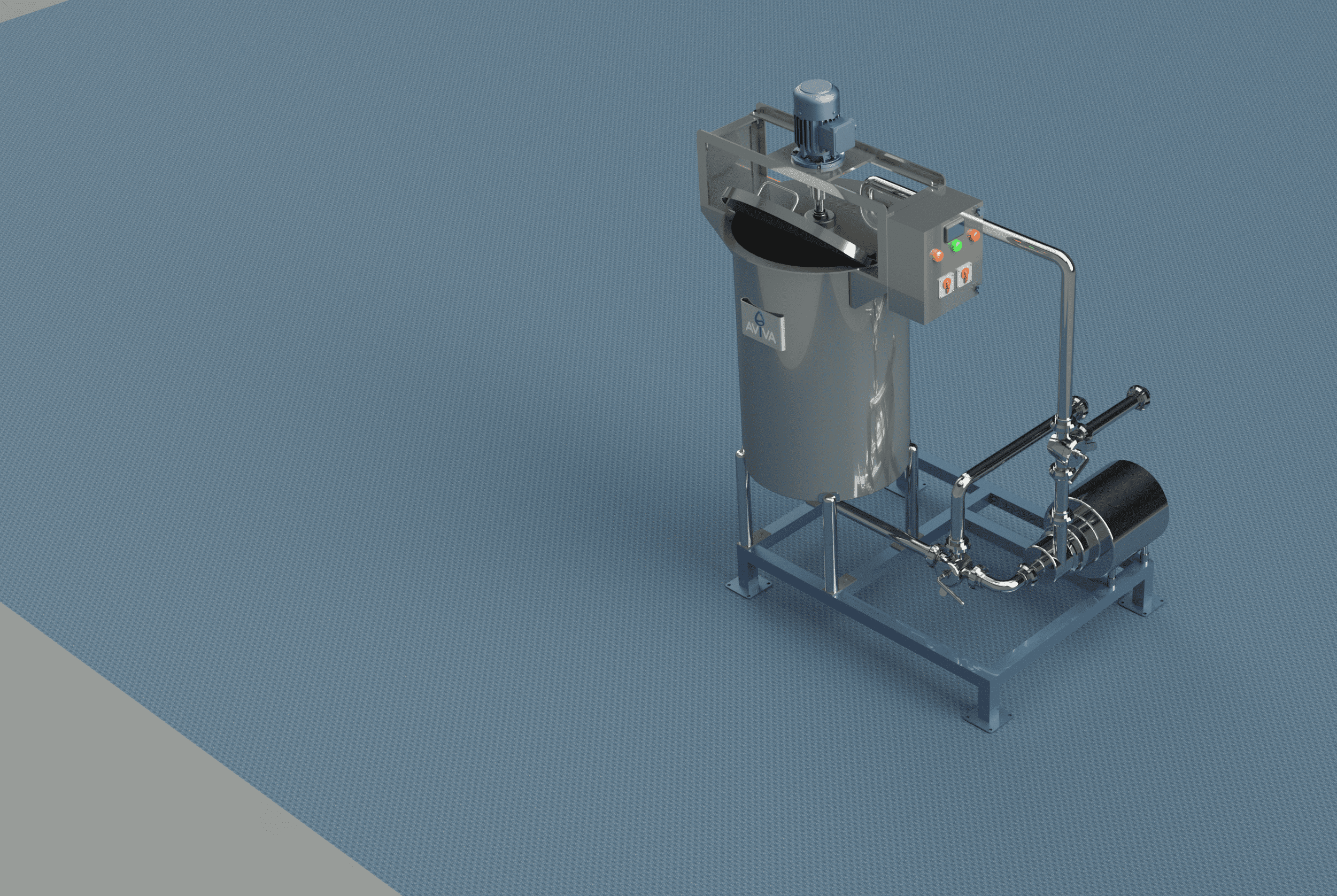

Mixing System

Mixing System Home Mixing System A mixing system is a setup or process used to combine different substances or ingredients to achieve a homogeneous…

Milk Filters Tanks

Milk Filters Tanks Home Milk Filter Tanks Manufacturer Milk filters and tanks play essential roles in dairy processing, ensuring that milk is clean, safe,…

Heat Recovery Units Tanks

Heat Recovery Units Tanks Home Heat Recovery Units Tanks Heat Recovery Units Tanks (HRUs) are devices used to recover waste heat generated from various…