CIP for Dairy plant

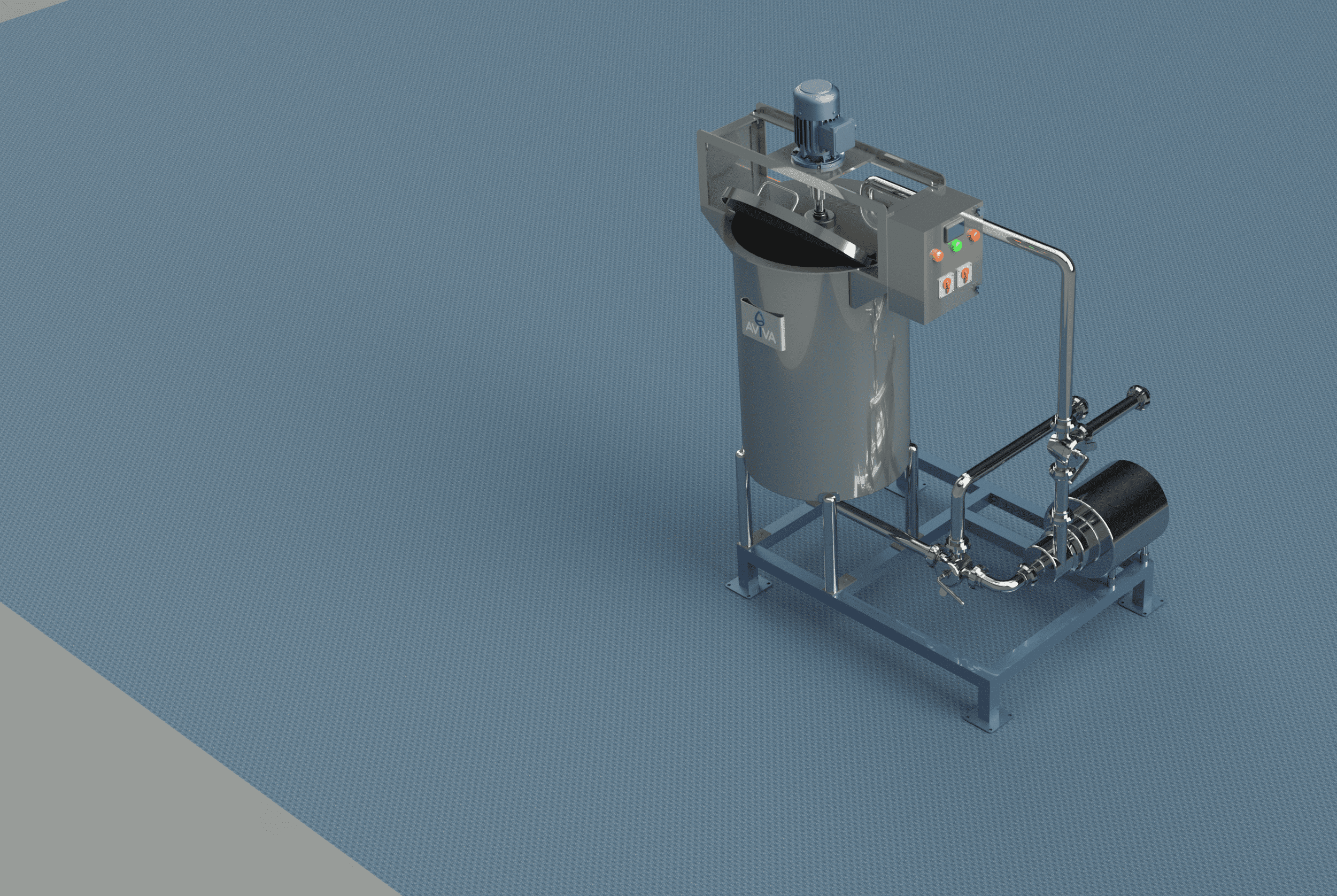

The CIP system stands for “Clean-in-Place” system. It’s a method used to clean the interior surfaces of pipes, vessels, process equipment, and associated fittings without disassembling them. We offer CIP for dairy plant. Here’s a brief description:

Purpose: The primary purpose of a CIP system is to remove product residues, contaminants, and microorganisms to prevent cross-contamination of subsequent product batches.

Components: Typical components include pumps, tanks, heat exchangers, valves, sensors, and control systems.

Process: The CIP process usually involves several steps:

- Pre-rinse: Water or cleaning solution is circulated through the system to remove gross contaminants.

- Cleaning: An alkaline or acidic cleaning solution is circulated to dissolve and remove residues.

- Rinse: Fresh water is used to rinse out remaining cleaning solution.

- Sanitization: Optional step using a sanitizing agent to kill microorganisms

- Final rinse: Purified water or a final rinse solution is used to ensure all cleaning agents are removed.

Automation: Many modern CIP systems are automated, controlled by PLCs (Programmable Logic Controllers) to ensure consistent and effective cleaning cycles.

Benefits: CIP systems reduce labor costs, minimize the risk of contamination, improve production efficiency by reducing downtime for cleaning, and ensure consistent cleaning results.

Is there anything specific you’d like to know more about regarding CIP systems?