Bearing OIl Washing Systems & Cabinets

“Bearing Oil Washing Systems & Cabinets” typically refer to equipment used for cleaning and maintaining bearings in industrial settings. Here’s a brief description of each:

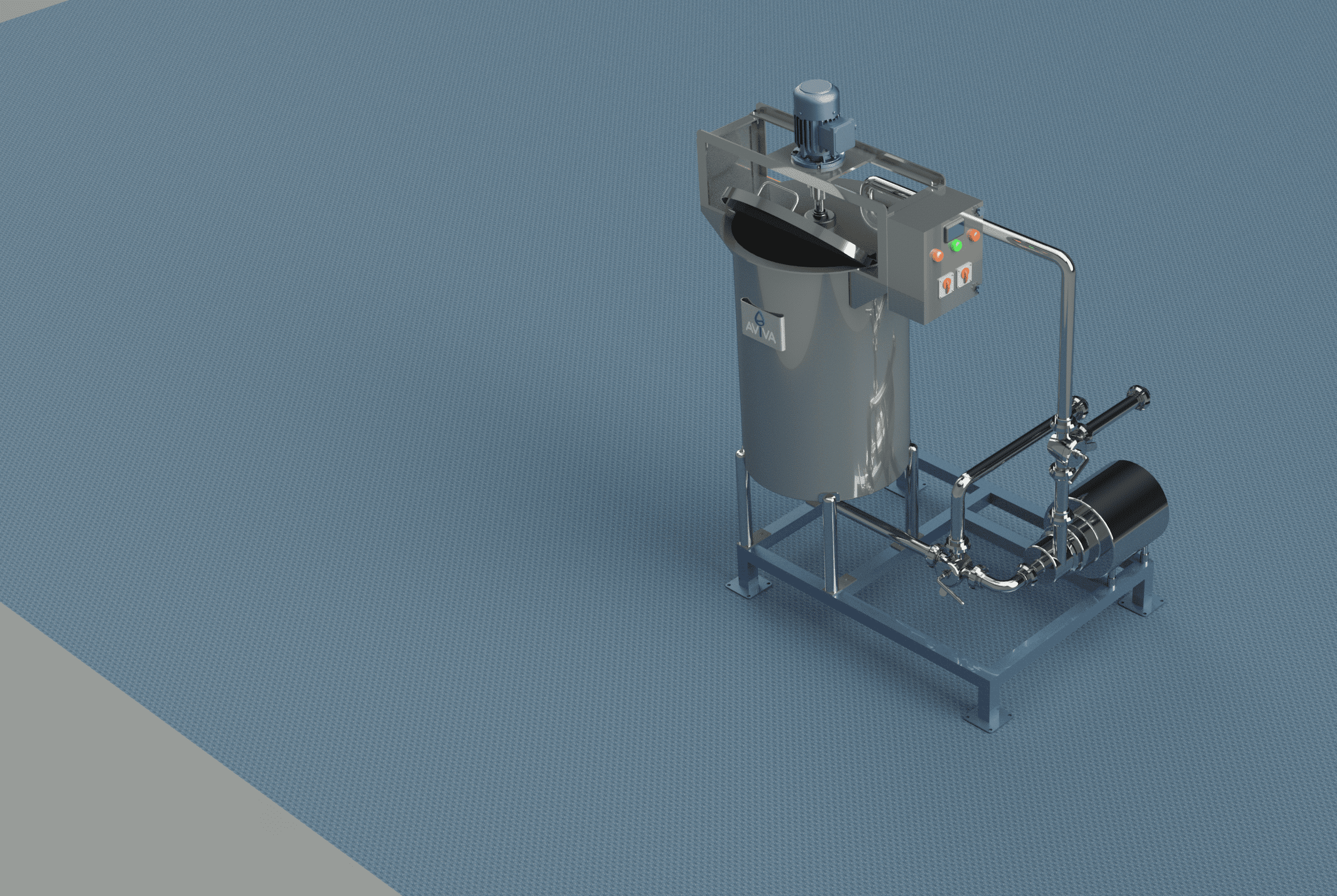

Bearing Oil Washing Systems:

Purpose: These systems are designed to clean bearings thoroughly to remove contaminants such as dirt, dust, and old oil.

Components: They usually include tanks for holding cleaning solvents or detergents, pumps for circulating the cleaning solution through the bearings, filters to remove debris, and sometimes heaters to improve cleaning effectiveness.

Operation: Bearings are typically placed in the system, where they undergo a series of cleaning cycles to ensure they are free from contaminants before being lubricated and put back into service.

Bearing Cabinets:

Purpose: These cabinets provide a controlled environment for storing bearings to prevent contamination and maintain their integrity.

Features: They often include shelves or racks designed to hold bearings securely, with seals or gaskets to keep out dust and moisture.

Types: Some cabinets are equipped with humidity and temperature controls to further protect bearings from environmental damage.

These systems and cabinets are crucial in maintaining the efficiency and longevity of bearings, which are critical components in machinery and industrial equipment.