Horizontal Milk Storage Tank

Horizontal milk storage tank is specialized designed for storing milk in a horizontal orientation. These tanks offer advantages in certain applications.

Like Milk Store, Process etc. These Tanks Commonly use in Inside the Plants Here are key points about horizontal milk storage tanks:

Design and Orientation: Horizontal milk storage tanks are constructed with a horizontal orientation, providing efficient space utilization.They are made from stainless steel for durability and hygiene Inside the Plants.

Capacity and Varieties: Capacities vary, with options like a 1000-liter to 30000 Liter in stainless steel tank. We offer both Single Compartment & Multi Compartment in Horizontal Design, that provide flexibility in Your choice.

Applications: Widely used in dairy processing and storage, these tanks contribute to efficient milk management

Horizontal milk storage tanks are a practical solution for certain dairy industry needs, offering efficiency and durability in milk storage.

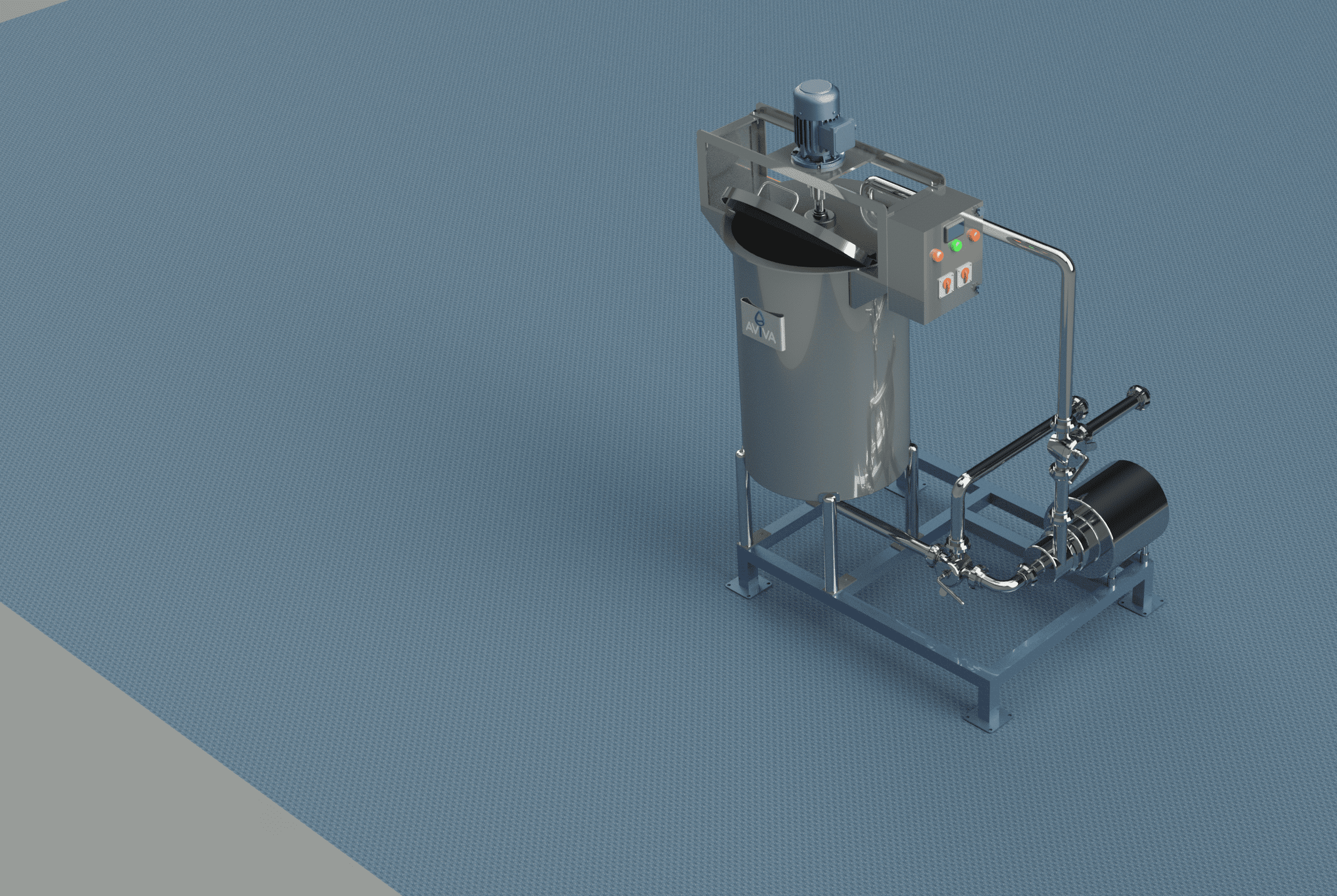

Features

Design: Unique, Occupies minimal space

- Temperature control: Multi Layers Insulated for Maintain Chilled Temp at 4°C

- Tank: Durable, AISI-304 S.S. Tanks with insulation

- Maintenance: User-friendly, low maintenance

- Sensors: Level Sensor & Pressure Level Sensor for Automation

- Agitator: Top Mounted Agitator Continuously rotates milk to maintain a uniform state

Technical Specifications

Design: Unique, Occupies minimal space

- Capacity Range: Horizontal milk storage tanks come in varying capacities, such as 1000 liters, to 30,000 Liters catering to the diverse needs of dairy farms and processing units.

- Gross capacity: 10% Extra for Rated Capacity

- Construction of Tank: AISI SS 304

- Tank Orientation– HorizontalType &completely closed type in Shape of Round.

- Base Structure–A Heavy Duty Mild Steel Pipes Structure with Two Coats Epoxy Primary theBase Structure can Stand with Load Capacity with Fully Filled Silos without any Damage.

- Inner Body: AISI SS 304

- Outer Body: AISI 304

- Milk measuring facility: High / Low Sensor, Pressure Level Sensor &Inside Wall Level Marking Visible from Sight Glass

- Agitators–Heavy Duty Gear Motors Top Mounted Agitators to Uniform Mixing Milk/Liquid

- Type of Insulation–Liquid Puff Injected or Multi Layers Insulation in the Form of Puff Sheet, Thermocol, LRB, Aluminum Foil & Bitumen.

- CIP Facility–High Speed Rotary Spray Ball for Inside Complete Cleaning

- Manway– Locking Type Manway Side/Top Mounted with food Grade Silicone Gasket

- Legs – Adjustable Conical Legs with 50 mm Height SS 316 Solid Ball Fit to Leveling the Tank

- Ladder–Heavy Duty Side Ladder made from Steel Pipes & Plates to approaching Top of Tanks

- Air vent– an Air vent top Mounted to Prevent Vacuums Generation During Milk Pump Milk Out Process

- Temperature Sensor–STD Thermowell PT 100with ½” BSP Coupling SS 304

- Inlet– No Foam Inlet with Expandable Union

- Light / Sight Glass– Light Glass with LED Bulb & Sight Glass for Check Milk Level Marking

- Walk Way Platform – Fully Weld Walkway Platform to Approach Gear Motor

- Lifting Lugs– Heavy SS 304 Cladded Lifting Lugs to Liftin Tanks

- Milk Outlet– SS 304 Flange Type Butter Fly Valve for Taking Out Milk

- Automation– Imported High Priscian Level Sensors &Pressor Level Transmitter Sensorsfor Exact Value of Milk Quantity in Milk Silo direct to Display in Control Panel in Plants & Office Area.

- Sampling Cock– 1” Inch Sampling Cock to Take Sample of Milk to Examine in Laboratory