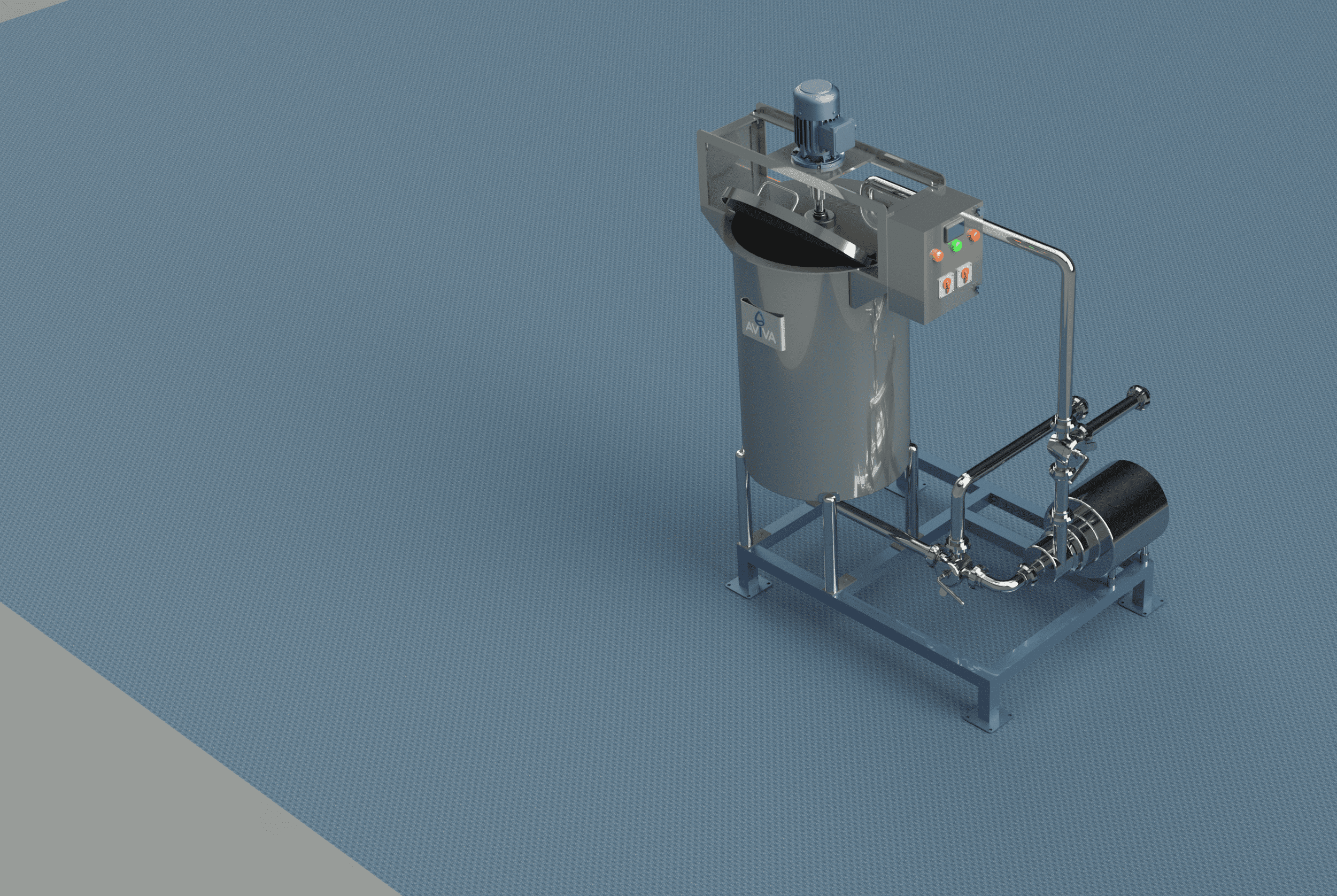

Bulk Milk Cooler 3000 Ltr

A Bulk Milk Cooler (BMC) is a large storage tank used by dairy Industries toChilling RawMilk. It’s a Main Part of dairy Industry& Dairy Products Process Plants, These Tanks usually made from stainless steel, and is cleaned by CIP after Complete each milk collection.

Aviva’s Bulk Milk Cooler 3000 Ltr have an enclosed design with an automatic cooling control unit and a Compact Control Panel with digital display to Easily Operate Complete BMCU System. The tank Having a 100 mm Thickness Polyurethane foam Insulation (Density 40 Kg)Injected by Machine. To Maintain Chilled Milk at Temp 4°CAEPL 3KL BMC Deigned by Special Construction, which allows them to Chilled milk 20 times faster. BMC have a 01 Nos Agitator with the RPM30- 32, to ensures the milk is the same temperature throughout the Day and prevents warm milk in the middle.

Features

Design: Unique, Occupies minimal space

- Temperature control: Digital temperature controller, advanced digital Technology to Control & Maintain temperature

- Cooling: Faster cooling due to direct expansion, energy efficient condensing unit

- Tank: Durable, AISI-304 S.S. Tanks with insulation

- Maintenance: User-friendly, low maintenance

- Electricity: Reduced electricity consumption

- Protection: Inbuilt anti-freezing protection system

- Microprocessor: Maintains temperature

- Agitator: Continuously rotates milk to maintain a uniform state

- Min Capacity of Milk Chilling Design – Special Design Omega Pillow Plates to Chill Milk Min 100 Liter Capacity Only by Operate one Condensing Unit at a Time

Technical Specifications

Design: Unique, Occupies minimal space

- Rated capacity: 3000 liters

- Gross capacity: 3300 liters

- Construction of Tank: AISI SS 304

- Tank Orientation– completely closed type in Shape of Elliptical & Horizontal

- Tank Evaporator– Omega Make Laser welded with Operating pressure of 30 bars and crash test pressure of 60 bars.

- Inner thickness: 2 mm AISI SS 304

- Outer thickness: 1.5 mm AISI 304

- Milk measuring facility: Inside Wall Mounted Dip stick &Calibration accuracy- 0.5%. Laminated & Framed calibration chart.

- Agitators– 01 Nos to Maintain Milk Temp & Compliance ensuring even distribution of the milk fat.

- Type of Insulation –100 mm thkInjected, CFC Free PUF 40kg/Cu. m. with the 0.019 Wm/k

- CIP Facility – Rotary Spray Ball 02 Nos for Inside Complete Cleaning

- Voltage range - Input Volts: 300 to 550 for 3-phase BMC Out Put Volts: 415

- Manway – Locking Type Manway Top Mounted

- Ball Fit – Adjustable 50 mm Height Solid Ball Fit to Leveling the Tank

- Ladder – Front Side Heavy Duty Ladder made from Pipes & Plates to approaching manway

- Air vent – an Air vent top Mounted to Prevent Vacuums Generation During Milk Pump Milk Out Process

- Temperature Sensor – Sub Zero

- Inlet – No Foam Inlet

- Pipe Line & Accessories - SS 304 Dairy Standard Union, NRV, 3 Way Valves etc. to Smooth Milk Loading Unloading Process in BMC.

- Servo Stabilizer: - 20 KVA – 3 Phase

- D.G Set Require – 20 KVA (Optional on Demand)– 3 Phase

Standard Applicable Cooling Time – First milking cycle (appx 50% to 60% of rated capacity of BMC tank) Cooling in less than 3 hours from 35C to 4°C- Second milking cycle (appx. 40% to 50% of rated capacity of BMC tank) cooling in 1hour 30 minutes (average temp 19.5 C to4°C)